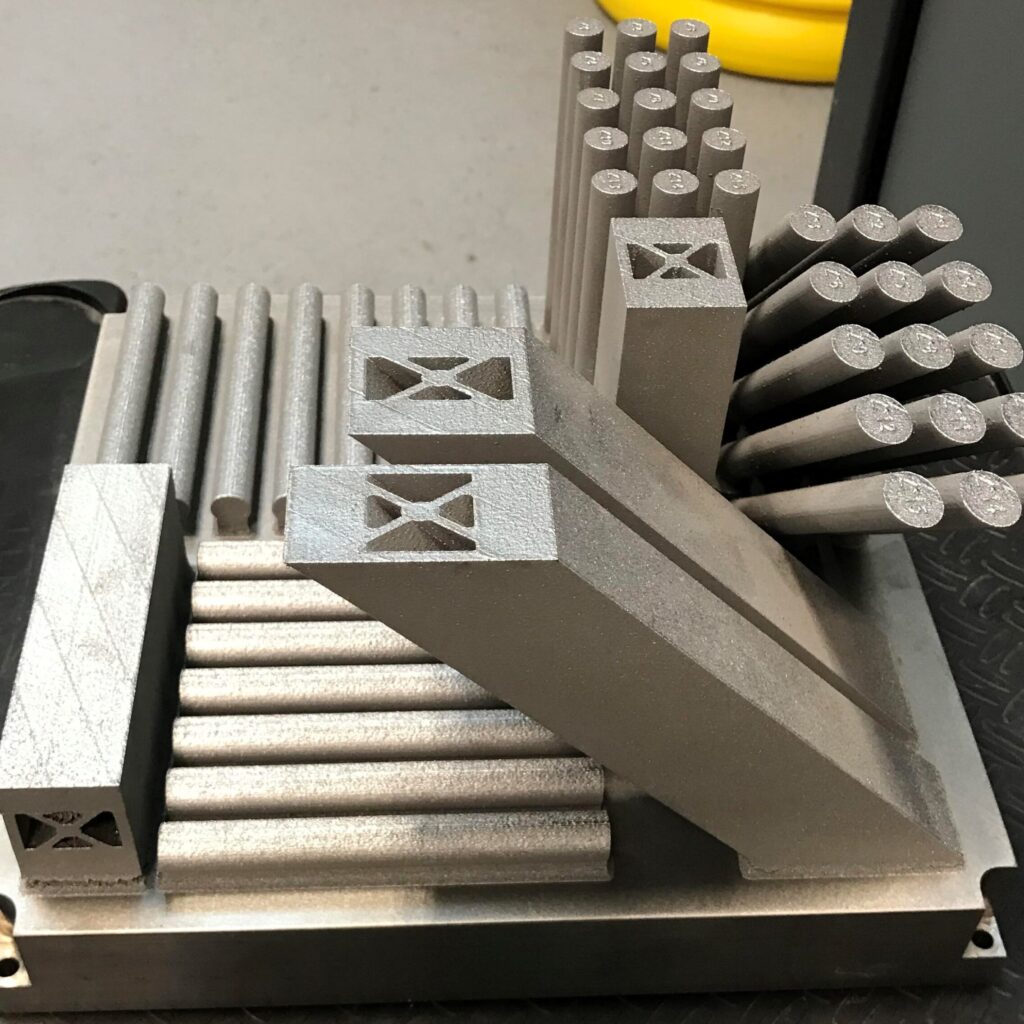

Predicting the Integrity of Additively Manufactured Nickel Alloys

This AFRL-funded MIDAS3 project aims to enhance the predictive capability for properties of geometrically complex components of nickel alloys fabricated by laser powder-bed fusion (LPBF)…

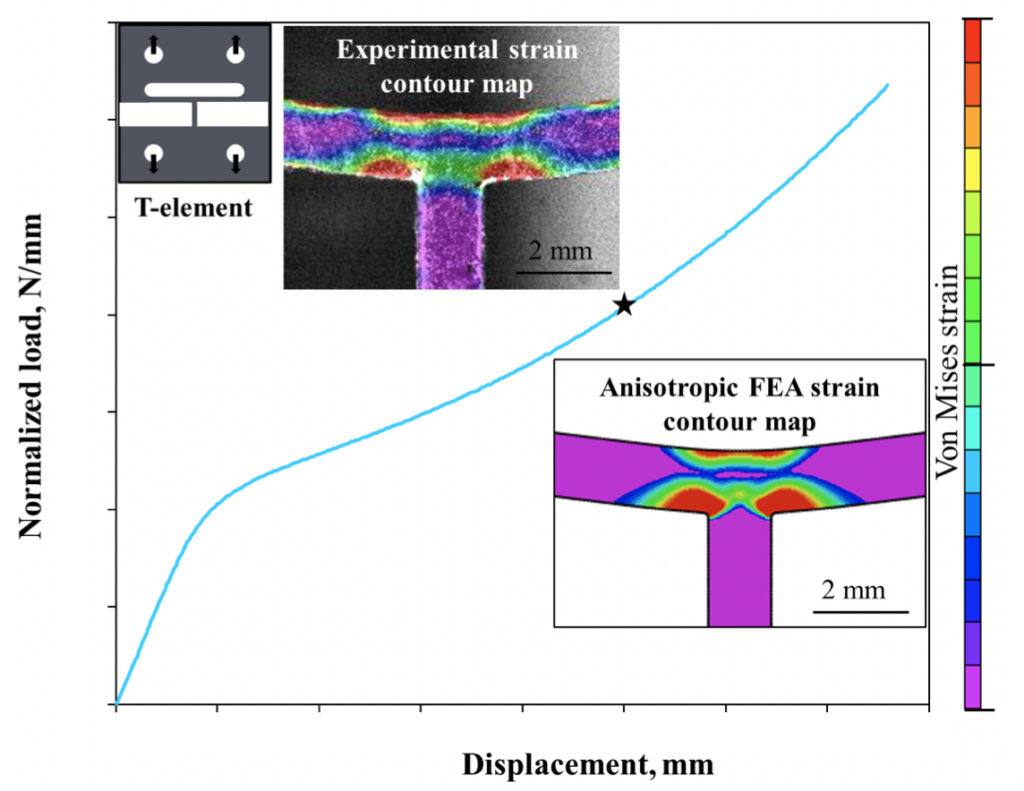

Design of 3D Woven Metallic Micro-lattices

Micro-lattices manufactured by advanced 3D weaving processes are emerging as an exciting architected material with multi-functional capabilities. Past work has shown that these materials can…

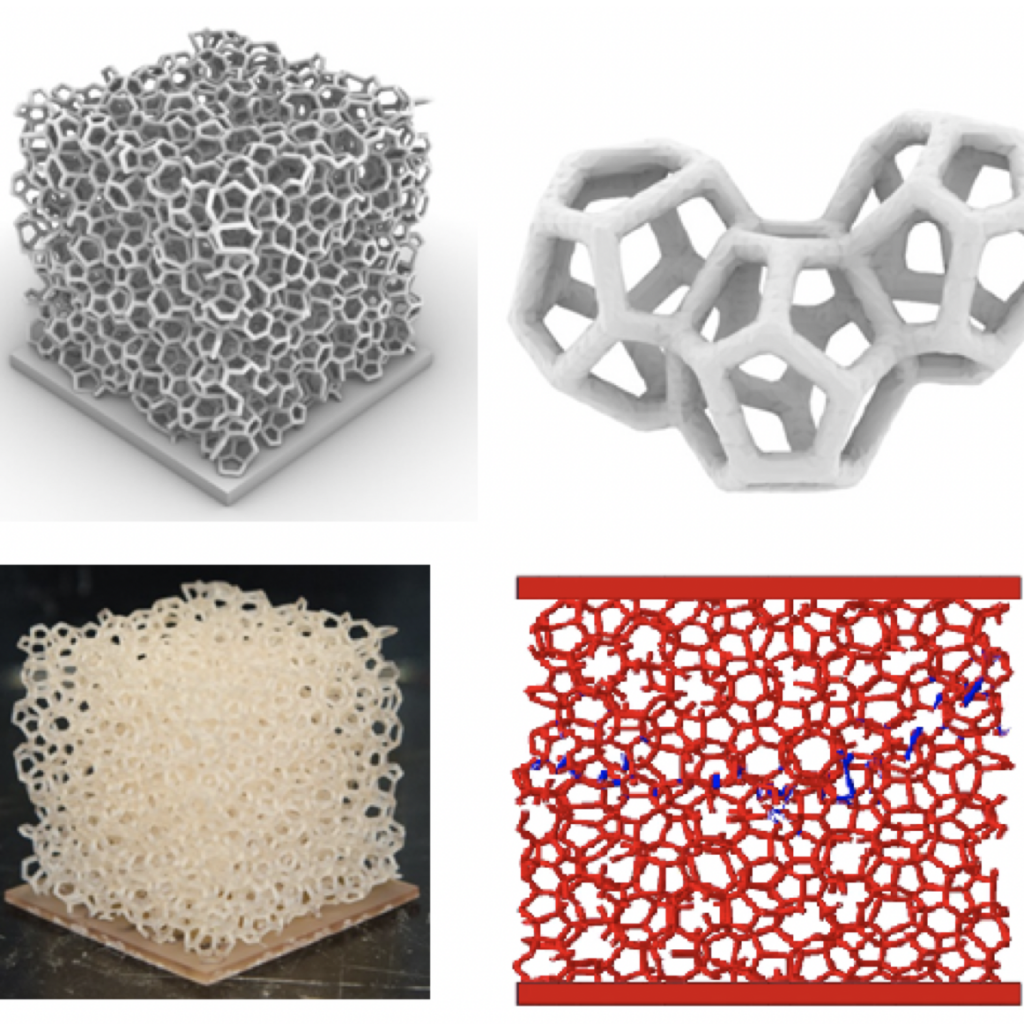

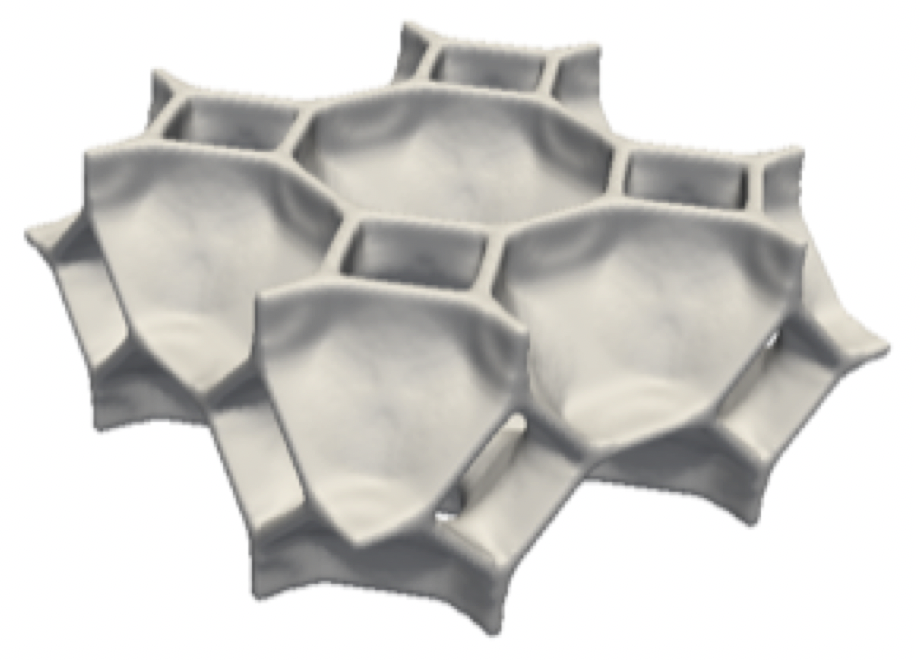

Strength and Toughness of Brittle Cellular Solids

Brittle cellular solids combine low weight with a large surface area and have thus found use in energy storage devices, filtration, acoustic insulation, armored textiles…

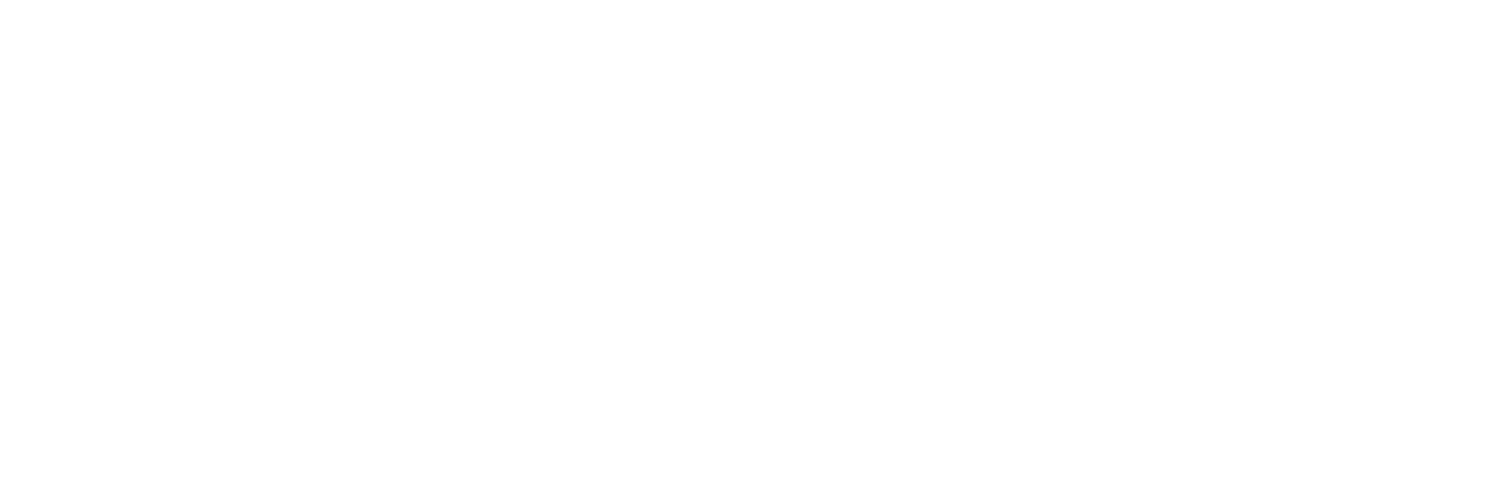

Anisotropy in Additively Manufactured Materials

This project aims to develop additively manufactured (AM) metallic materials and components offering exceptional and fully customizable combinations of mass, strength and stiffness. In collaboration…

COVID-19 Response: 3D-Printed Components

In the midst of ventilator and personal protective equipment shortages due to COVID-19, JAM2 researchers collaborated with colleagues across JHU and other universities to design…

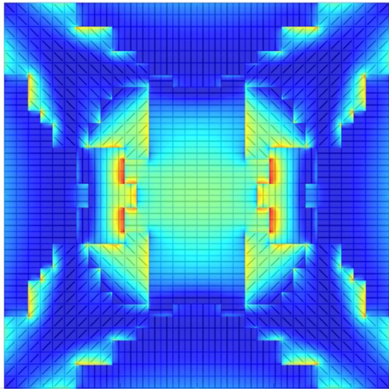

Topology optimization for CNT composites

This project is based in NASA’s Ultra-Strong Composites by Computational Design (US-COMP) Space Technology Research Institute, aimed at developing new materials to meet stiffness and strength demands…

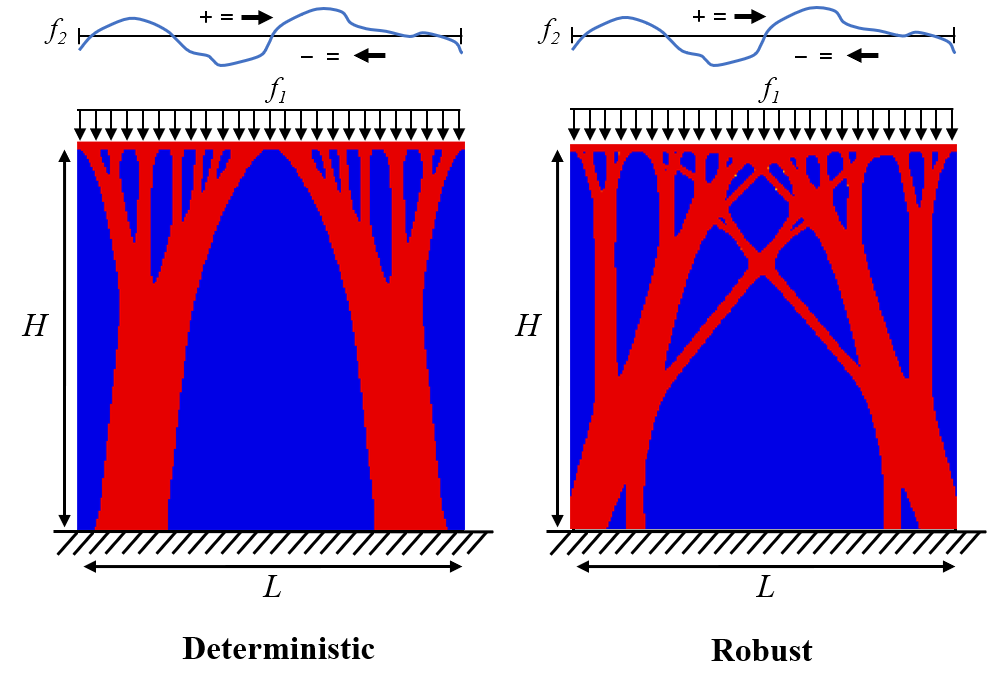

Topology Optimization of Additively Manufactured Structures Accounting for Variabilities

This project seeks to develop design methods that account for uncertainties that may arise in the manufacture and operation of components and structures produced through…

Topology Optimization of Lightweight, Additively Manufactured Material Systems for Space

This NASA Early Stage Innovation (ESI) project seeks to exploit the design freedom provided by additive manufacturing (AM) by integrating the free-form design approach of…