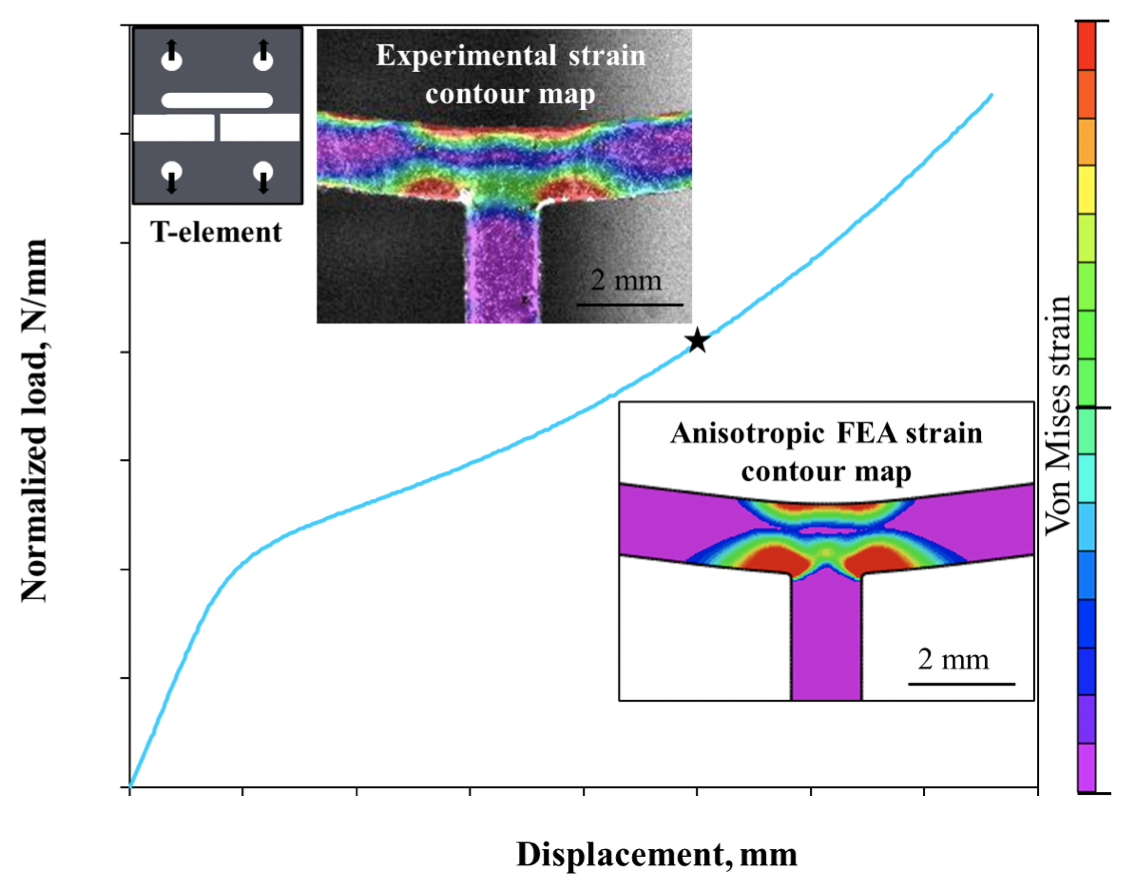

This AFRL-funded MIDAS3 project aims to enhance the predictive capability for properties of geometrically complex components of nickel alloys fabricated by laser powder-bed fusion (LPBF) approach. The program is divided into two major tasks. First, the tensile and resonant properties of printed Ni alloys as a function of print conditions will be investigated experimentally. Second, thin-walled elements with microstructures and properties similar to thin-walled aerospace components will be designed, printed and mechanically tested. The experimental results from both the studies will allow the development of calibrated models that account for the inhomogeneities and anisotropy inherent in such printed parts. Having a simple simulation framework, guided by experiments, will further enable the use of topology optimization to probe the design space for structural PBF components and lattices.

Predicting the Integrity of Additively Manufactured Nickel Alloys

Characterization, Modeling and Design of AM Materials

Kevin Hemker (PI)

Additional Team Members:

Tresa Pollock, UCSB

Matthew Begley, UCSB

Jamie Guest, JHU

Chris Torbet, UCSB

Marie Cox, AFRL

William Musinski, AFRL

Paul Shade, AFRL

Arunima Banerjee (GS), JHU

Jeff Rossin (GS), UCSB

Sara Messina (GS), UCSB

Mo-Rigen He, JHU