About Us

The Johns Hopkins Center for Additive Manufacturing and Architected Materials (JAM2) brings together faculty, staff, students, and post-docs from across Johns Hopkins to conduct cross-cutting research in design, manufacturing, characterization and applications of additive manufacturing and architected materials.

Our Goal

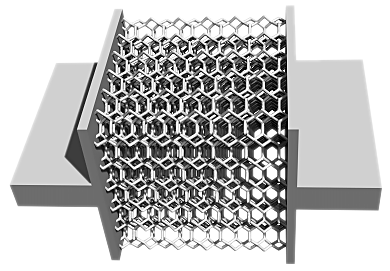

Our goal is to revolutionize material performance for a broad array of engineering applications, including automotive, aviation, defense, energy, healthcare, medicine, and space. The emergence of additive manufacturing has ushered in exciting new possibilities for the fabrication of materials and components with unique shapes and internal architectures. Empowering scientists and engineers with the ability to design and control the internal architecture of a material allows them to create materials with optimized properties far superior to those made by traditional methods. JAM2 researchers are at the fore-front of this new frontier in materials development.

Focus Areas

Advanced Aerospace

Biomedical Implants

Design Optimization

Energy Applications

Manufacturing Technology

Multifunctional Materials and Structures

Materials Characterization

Why AM2?

Initial thrust areas at JAM2 include the development of:

- Lightweight materials and components for aircraft and spacecraft

- Materials for use in pediatric cardiovascular devices, as well as enhanced bone and tissue scaffolds

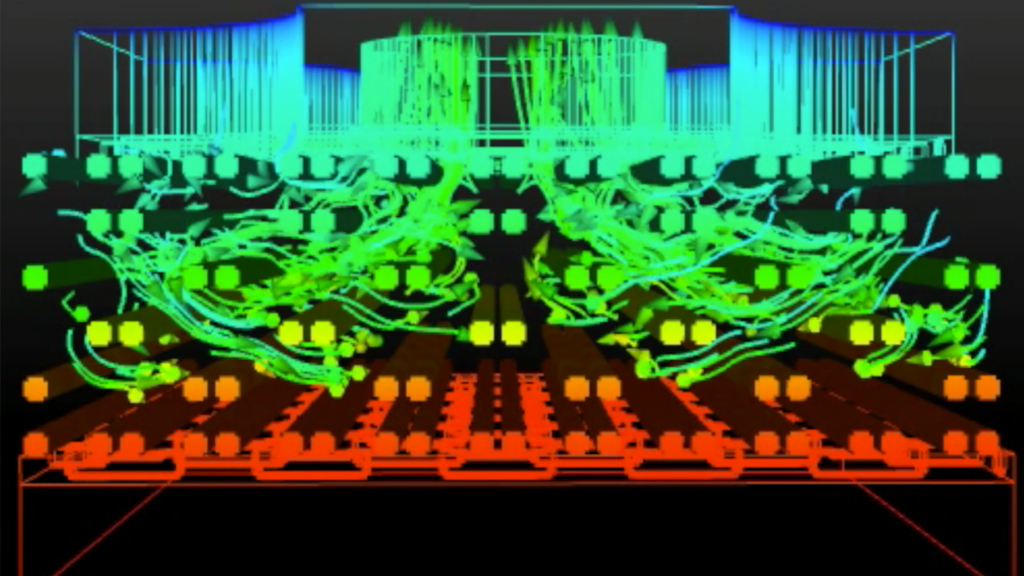

- Ultra-efficient heat exchangers and self-adaptive energy harvesting devices

- Fundamental, multi-scale investigation of 3-D printed polymers

- Multifunctional load-bearing structures for thermal management and vibration damping